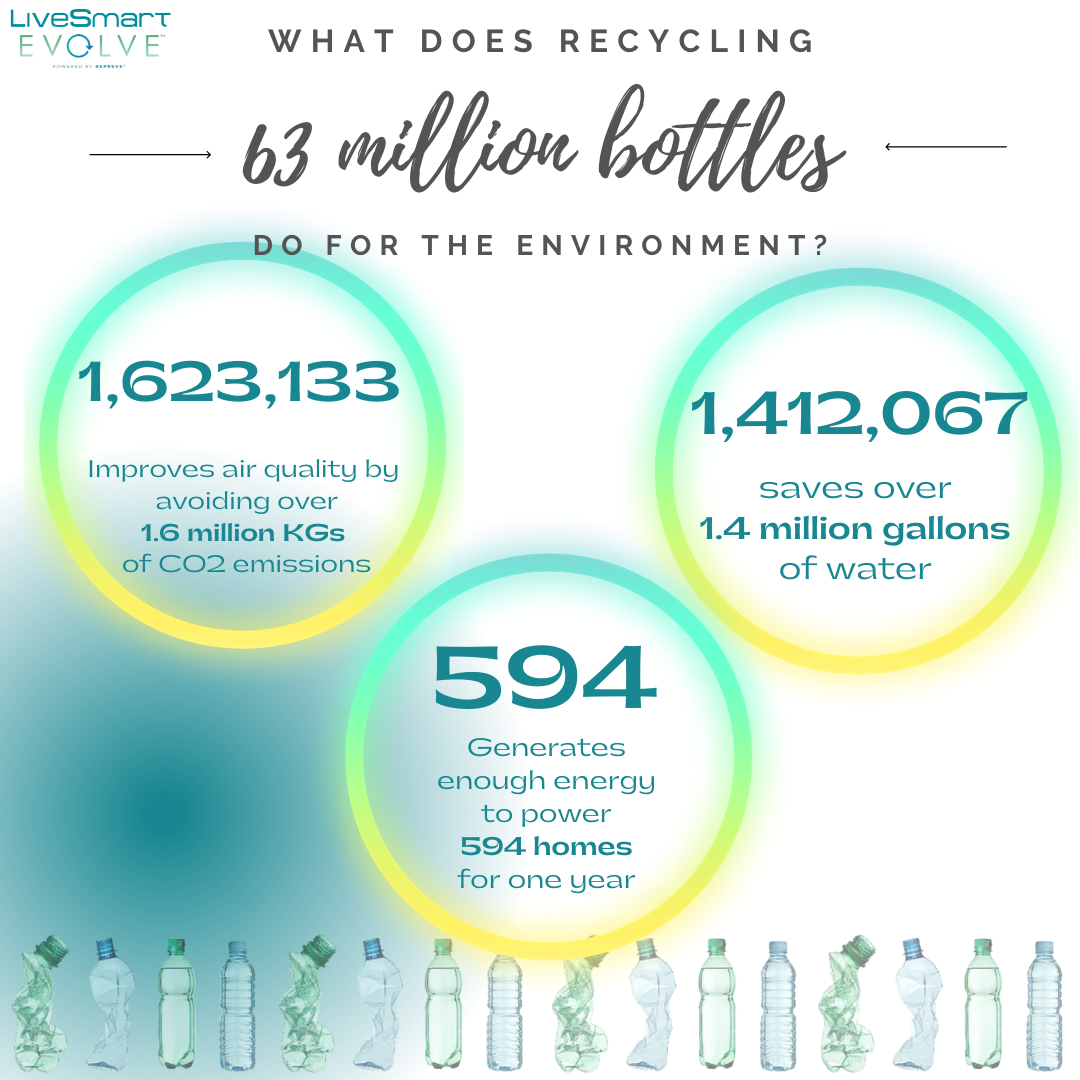

HIGH POINT, N.C. (MAY 18, 2021) ─ Culp, Inc. (NYSE: CULP) (together with its consolidated subsidiaries, “CULP”) continues to advance its efforts to promote environmental sustainability, announcing today that since the introduction of its LiveSmart Evolve® fabric line in 2019, CULP has helped divert over 63 million plastic bottles out of waste streams by incorporating REPREVE® recycled fiber into its upholstery and mattress fabrics products, including its LiveSmart Evolve fabric line. LiveSmart Evolve is made with at least 30% or more of REPREVE yarn, a high-quality polyester yarn made by North Carolina-based Unifi, Inc. from recycled post-consumer plastic bottles. Due to the pandemic and an increased consumer focus on the safety and comfort of the home, CULP has seen strong interest across its LiveSmart® portfolio of performance fabric products, including LiveSmart Outdoor®, LiveSmart Ultra™, LiveSmart Barrier Plus™, and LiveSmart Evolve®. The company, as part of its commitment to environmental responsibility, has worked to strongly promote its LiveSmart Evolve line as a product that builds on the stain-resistance and cleanability of its LiveSmart® performance fabrics by bettering the planet and offering environmentally-conscious consumers the ability to be a part of positive change to conserve natural resources.

“CULP is grateful to have such a strong relationship with Unifi, and the use of REPREVE in our upholstery fabrics has been a phenomenal success,” states Tammy Buckner, senior vice-president of marketing and design for Culp Upholstery Fabrics. “At least 80 percent of plastic flows into the oceans from land, totaling over 8 million tons per year. But we’ve worked to turn this negative into a positive through our LiveSmart Evolve sustainability line. Demand for fabrics with a sustainability focus has been propelled during the pandemic. It is no longer just words, but consumers are taking action to make sure their home purchases reflect their own commitment to bettering the environment. By incorporating REPREVE yarn into our fabric, we are working to reduce the plastic problem before it enters our landfills, rivers and oceans.”

Commenting on their combined efforts, Brian Moore, vice-president of global brand sales for Unifi, Inc. states, “Our partnership with CULP is a win-win for the environment. Together, we're able to transform plastic bottles into REPREVE recycled fiber and give them a second life while combining sustainability and performance. We're proud to work today for the good of tomorrow."

CULP also continues its focus on developing additional product lines designed for environmental sustainability, including mattress fabrics designed with certain recycled and biodegradable content. “Utilizing recycled material and design that is dedicated to creating durable and long-lasting products, CULP is committed to being a part of the circular economy that keeps our products (and waste) out of landfills,” added Buckner.

In addition to CULP’s focus on environmental responsibility through its products, the company is also committed to other sustainability initiatives in its manufacturing and daily operations, such as the reduction of energy, water use, and waste. The company’s production facility in Quebec, Canada uses 99.8% hydro and wind power to provide clean renewable energy, and its production plant in Knoxville, TN uses solar power for its operations. The company also practices water conservation and re-use at its Stokesdale, NC facility, and utilizes paper recycling programs across all of its U.S. and Canadian facilities. Additionally, in 2020, the company achieved landfill free status at all U.S. manufacturing facilities for its mattress fabrics division, and in 2021, the company joined the Sustainable Furnishings Council to help raise awareness and promote the adoption of environmentally sustainable practices in the home furnishings industry.